Manufacturing

6.000 m² of manufacturing surface

Quality, durability and service

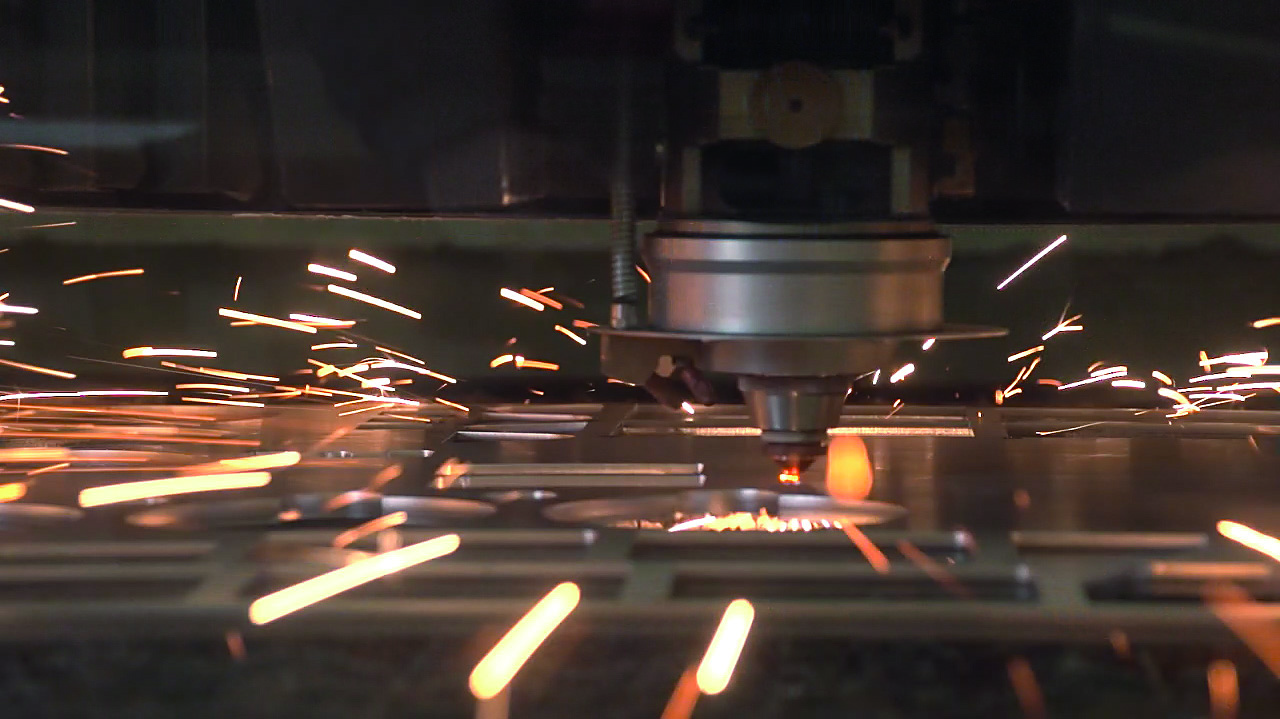

At Gernal, we build our machines from scratch in our 6000 m² manufacturing plant. We are vertically integrated and manage all steps of the manufacturing process.

This process kicks off with our engineering department. Our own engineers design your most suitable machine. Once the plans are drawn up, our craftsmen set about building and assembling your machine. This process only ends once your new food processing line is up and running. Then comes our after-sales department.

Our deliberate choice for vertical integration is advantageous in many ways:

-

extensive product range

-

customization

-

easy and direct lines of communication

-

speed and flexibility

Quality and excellence, even for pre-owned machinery

All our pre-owned machines are serviced and restored by our own staff. If necessary, faulty components are replaced. That way, we can deliver reliable installations.

Our extensive quality checks guarantee the finest machinery with the least malfunctions.

Experts in food processing technology

All employees are experts in their domain and work with the highest level of precision and care.

Our short lines of communication ensure a swift completion of your project. Together we will find an innovating and fitting solution.