Catalogus

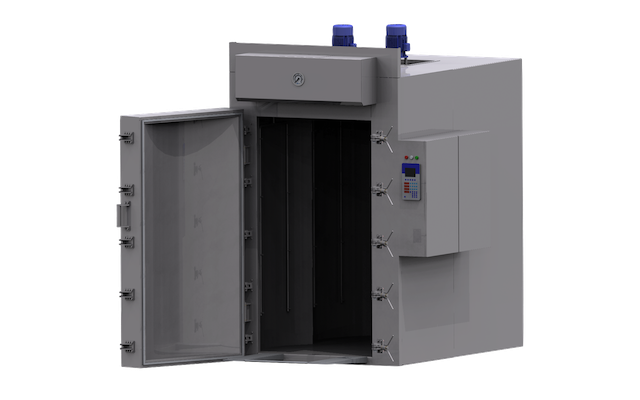

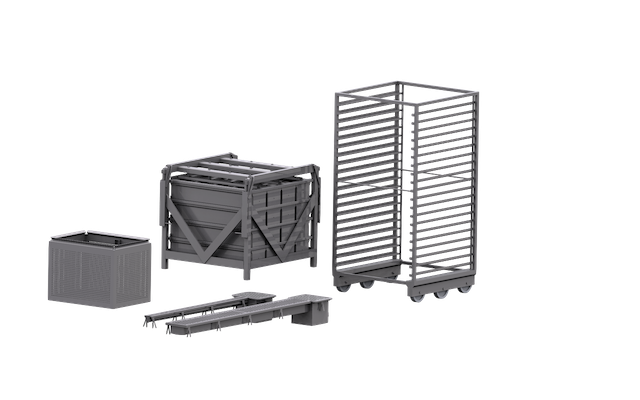

Uitgebreide catalogus met kant-en-klare oplossingen

Tweedehands

Volledig gereviseerde machines

Maatwerk

Gernal beschikt over een eigen R&D afdeling met ervaren engineers. Voor specifieke behoeftes bieden wij ook machines op maat.

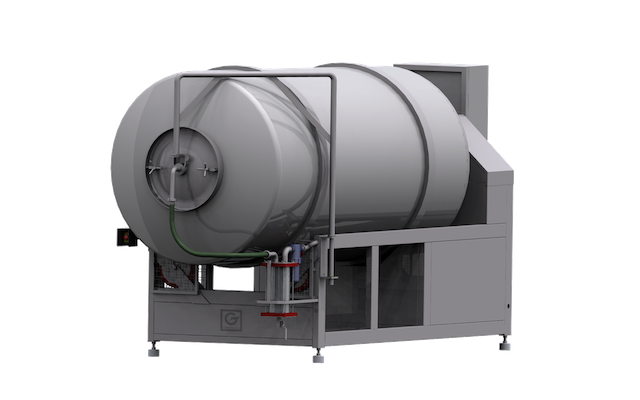

Ontwerp, productie en assemblage van machines

voor de voedingsindustrie

Laatste nieuws

Wij zijn Gernal

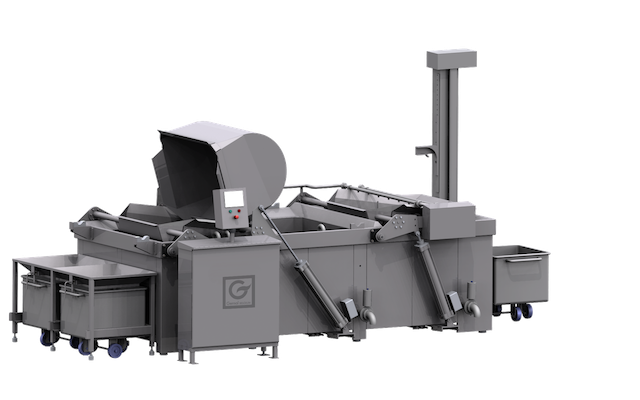

Standaard oplossingen of maatwerk machines

Gernal heeft al meer dan 50 jaar ervaring in de voedingssector. Wij zijn de machinebouwer voor de voedingsindustrie. Het bedrijf ontwerpt, produceert en assembleert hoogkwalitatieve machines en productielijnen die in de voedingssector worden ingezet.

Ruime kennis & ervaring in de voedingsindustrie.

Gernal maakt talrijke gebruiksklare oplossingen die voor iedereen gebruiksvriendelijk zijn en kwalitatief van het hoogste niveau zijn. Naast de standaard oplossingen kunt u ook terecht bij Gernal voor producten op maat. Samen met u doktert Gernal een de meest gepaste oplossing voor uw wensen en noden. Ons team van experten heeft een ruime kennis en jarenlange ervaring waardoor zij u deskundig en betrouwbaar advies kunnen verschaffen. Daarnaast werkt Gernal met de nieuwste technologieën die zorgen voor een optimale ontwikkeling en productie van onze machines.

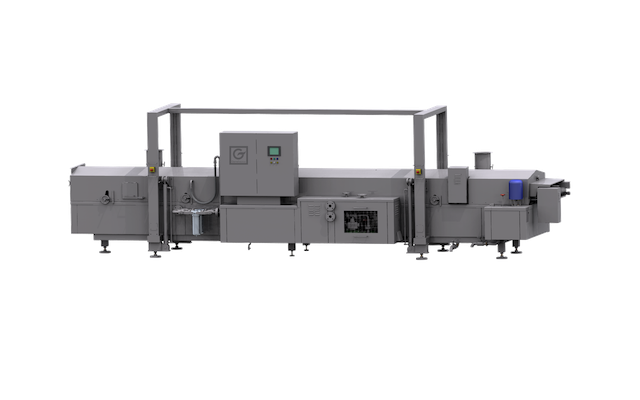

Een vooruitstrevende service

in binnen- en buitenland

Dankzij een nauwe samenwerking met de voedingsindustrie kan Gernal de meest gepaste machines aanbieden voor de meest specifieke noden van uw bedrijf. De Gernal machines en dienst na verkoop zorgen voor de meest efficiënte productie van uw vleeswaren, gevogelte, vis, groenten of bereide maaltijden.

Ons team en onze machines genieten niet enkel een reputatie in België maar ook in het buitenland. Meer dan de helft van onze machines worden geëxporteerd over heel de wereld.

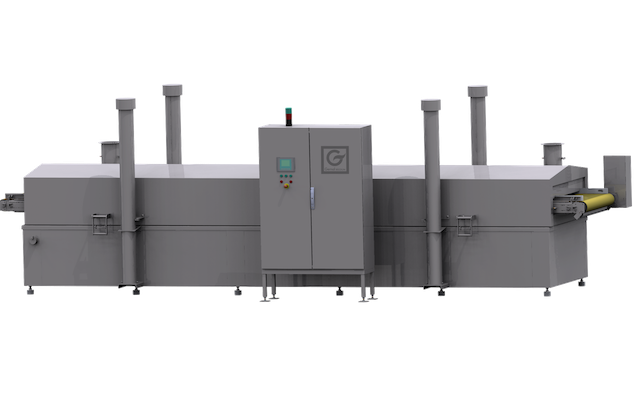

Uitstekende dienst na verkoop

Gernal levert geen machines, maar oplossingen. Dat merkt u meteen aan de dienst na verkoop. De oplossingen van Gernal vormen het hart van uw productie. Betrouwbaarheid is een must!

De Gernal service is een essentiëel deel van ons bedrijf. Wij stoppen niet bij de installatie van uw machine maar staan tijdens uw productieproces steeds klaar voor advies en technische ondersteuning. We gaan steeds samen op zoek naar de beste oplossing en reparatie voor eventuele storingen en problemen.